Size Range: | DN80-DN200 |

Pressure Classes: | PN16 |

Coating: | AS/NZS 4020 Approved,Fusion Bonded Epoxy |

Temperature Range: | -10℃ to 80℃ |

Flange Drilling Connection: | AS/NZS 4087 CL16 |

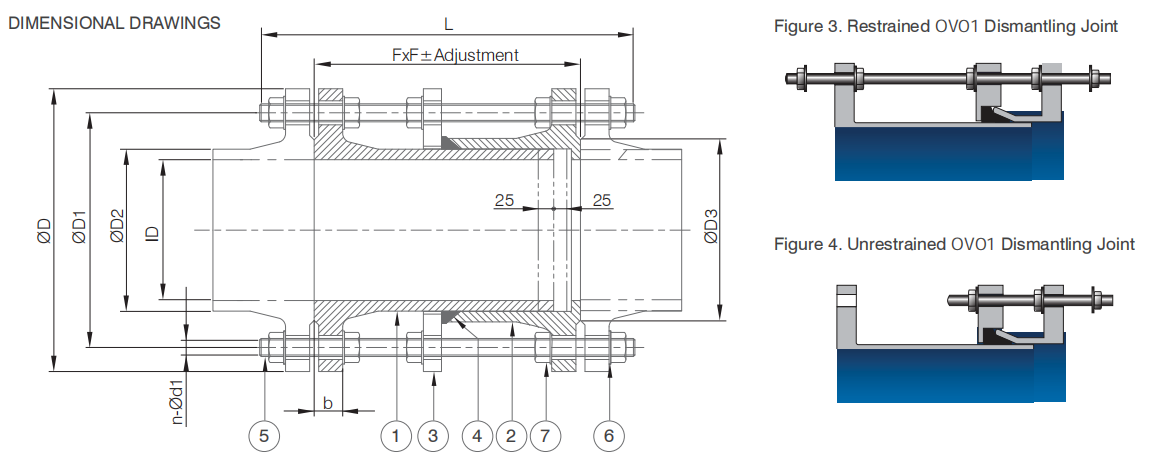

| NO. | DESCRIPTION | MATERIAL |

| 1 | Flanged Spigot Long | Ductile Iron (fusion bonded epoxy coated) |

| 2 | Flanged Spigot Short | Ductile Iron (fusion bonded epoxy coated) |

| 3 | Sealing Flange | Ductile Iron (fusion bonded epoxy coated) |

| 4 | Sealing Ring | EPDM |

| 5 | Tie Rod | Stainless Steel (Teflon® coated) |

| 6 | Washer | Stainless Steel 316 |

| 7 | Nut | Stainless Steel 316 |

| NOMINAL PRESSURE | PN16 | |

Test: | Strength Test | 24Bar |

| Pressure: | Sealing Test | 17.6Bar |

| Max Working Temperature: | -10ºC to +80ºC |

| OV01 DN80 - DN1200 | FLANGE DRILLING AS/NZS 4087 CL16 | NO. OF TIE RODS | |||||||||||

| DN | ID | L | FxF | Adjustment | b | ØD | ØD1 | ØD2 | ØD3 | n-Ød1 | 25% Restrained | 50% Restrained | 100% Restrained |

| 80 | 83 | 340 | 205 | ±25 | 19 | 185 | 146 | 98 | 122 | 4-M16 | 4 | ||

| 100 | 101 | 340 | 205 | ±25 | 19 | 215 | 178 | 118 | 154 | 4-M16 | 4 | 4 | |

| 150 | 154 | 340 | 205 | ±25 | 19 | 280 | 235 | 170 | 186 | 8-M16 | 4 | 8 | |

| 200 | 206 | 350 | 215 | ±25 | 20 | 335 | 292 | 222 | 211 | 8-M16 | 4 | 8 | |

| 250 | 258 | 380 | 220 | ±25 | 22 | 405 | 356 | 274 | 328 | 8-M16 | 3 | 6 | 8 |

| 300 | 307 | 400 | 240 | ±25 | 25 | 455 | 406 | 326 | 378 | 12-M20 | 3 | 6 | 12 |

| 350 | 359 | 410 | 240 | ±25 | 27 | 525 | 470 | 378 | 438 | 12-M24 | 3 | 6 | 12 |

| 375 | 400 | 430 | 250 | ±25 | 28 | 550 | 495 | 406 | 463 | 12-M24 | 3 | 6 | 12 |

| 400 | 408 | 430 | 250 | ±25 | 28 | 580 | 521 | 429 | 489 | 12-M24 | 3 | 6 | 12 |

| 450 | 456 | 450 | 265 | ±25 | 30 | 640 | 584 | 480 | 532 | 12-M24 | 3 | 6 | 12 |

| 500 | 508 | 460 | 275 | ±25 | 32 | 705 | 641 | 532 | 609 | 16-M24 | 4 | 8 | 16 |

| 600 | 613 | 500 | 295 | ±25 | 36 | 825 | 756 | 635 | 717 | 16-M27 | 4 | 8 | 16 |

| 700 | 711 | 530 | 300 | ±25 | 40 | 910 | 845 | 738 | 806 | 20-M27 | 5 | 10 | 20 |

| 750 | 760 | 530 | 320 | ±25 | 43 | 995 | 927 | 775 | 888 | 20-M30 | 5 | 10 | 20 |

| 800 | 817 | 560 | 320 | ±25 | 43 | 1060 | 984 | 842 | 942 | 20-M33 | 5 | 10 | 20 |

| 900 | 911 | 580 | 320 | ±25 | 47 | 1175 | 1092 | 945 | 1050 | 24-M33 | 6 | 12 | 24 |

| 1000 | 1012 | 600 | 330 | ±25 | 50 | 1255 | 1175 | 1048 | 1130 | 24-M33 | 6 | 12 | 24 |

| 1200 | 1216 | 640 | 350 | ±25 | 57 | 1490 | 1410 | 1255 | 1365 | 24-M33 | 6 | 12 | 32 |

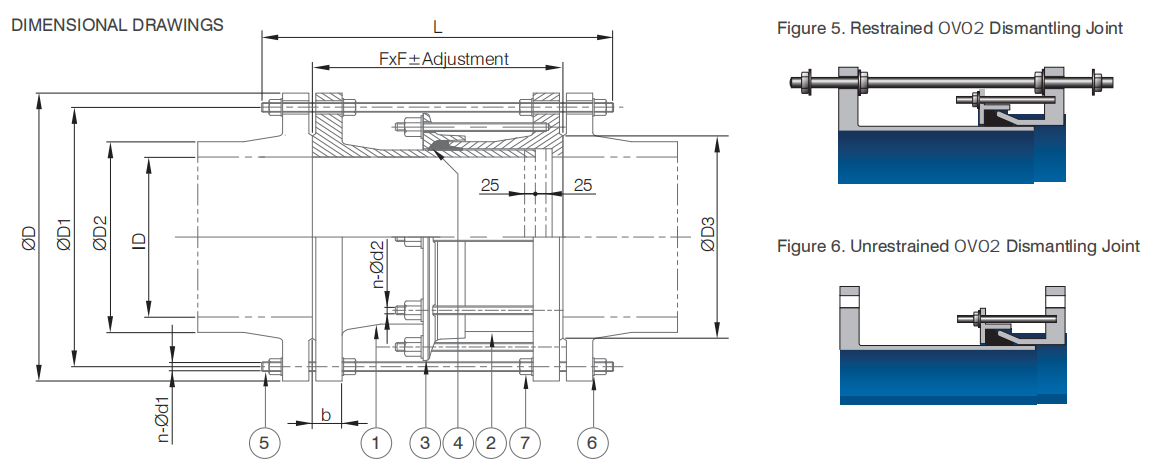

| NO. | DESCRIPTION | MATERIAL |

| 1 | Flanged Spigot Long | Ductile Iron (fusion bonded epoxy coated) |

| 2 | Flanged Spigot Short | Ductile Iron (fusion bonded epoxy coated) |

| 3 | Sealing Flange | Ductile Iron (fusion bonded epoxy coated) |

| 4 | Sealing Ring | EPDM |

| 5 | Tie Rod | Stainless Steel (Teflon® coated) |

| 6 | Washer | Stainless Steel 316 |

| 7 | Nut | Stainless Steel 316 |

| NOMINAL PRESSURE | PN16 | |

| Test: | Strength Test | 24Bar |

| Pressure: | Sealing Test | 17.6Bar |

| Max Working Temperature: | -10ºC to +80ºC |

| OV02 DN80 - DN1200 | FLANGE DRILLING AS/NZS 4087 CL16 & TIE RODS DETAILS | |||||||||||

| DN | ID | L | FxF | Adjustment | b | ØD | ØD1 | ØD2 | ØD3 | n-Ød1 | n-Ød2 | NO. OF TIE RODS |

| 80 | 83 | 330 | 205 | ±25 | 19 | 185 | 146 | 98 | 122 | 4-18mm | 4-M12 | 4-M16*330mm |

| 100 | 101 | 330 | 205 | ±25 | 19 | 215 | 178 | 118 | 154 | 4-18mm | 4-M12 | 4-M16*330mm |

| 150 | 154 | 330 | 205 | ±25 | 19 | 280 | 235 | 170 | 186 | 8-18mm | 4-M12 | 4-M16*330mm |

| 200 | 206 | 350 | 215 | ±25 | 20 | 335 | 292 | 222 | 211 | 8-18mm | 4-M12 | 4-M16*350mm |

| 250 | 258 | 380 | 220 | ±25 | 22 | 405 | 356 | 274 | 328 | 8-22mm | 4-M12 | 4-M20*380mm |

| 300 | 307 | 400 | 240 | ±25 | 25 | 455 | 406 | 326 | 378 | 12-22mm | 6-M12 | 4-M20*400mm |

| 350 | 359 | 410 | 240 | ±25 | 27 | 525 | 470 | 378 | 438 | 12-26mm | 6-M16 | 4-M24*410mm |

| 375 | 400 | 430 | 250 | ±25 | 28 | 550 | 495 | 406 | 463 | 12-26mm | 6-M16 | 4-M24*430mm |

| 400 | 408 | 430 | 250 | ±25 | 28 | 580 | 521 | 429 | 489 | 12-26mm | 6-M16 | 4-M24*430mm |

| 450 | 456 | 450 | 265 | ±25 | 30 | 640 | 584 | 480 | 532 | 12-26mm | 6-M16 | 4-M24*450mm |

| 500 | 508 | 460 | 275 | ±25 | 32 | 705 | 641 | 532 | 609 | 16-26mm | 8-M16 | 4-M24*460mm |

| 600 | 613 | 500 | 295 | ±25 | 36 | 825 | 756 | 635 | 717 | 16-30mm | 8-M16 | 4-M27*500mm |

| 700 | 711 | 510 | 295 | ±25 | 40 | 910 | 845 | 738 | 806 | 20-30mm | 10-M16 | 5-M27*510mm |

| 750 | 788 | 530 | 320 | ±25 | 41 | 995 | 927 | 813 | 888 | 20-33mm | 10-M16 | 5-M30*530mm |

| 800 | 817 | 560 | 320 | ±25 | 43 | 1060 | 984 | 842 | 942 | 20-36mm | 10-M16 | 5-M33*560mm |

| 900 | 911 | 580 | 320 | ±25 | 47 | 1175 | 1092 | 945 | 1050 | 24-36mm | 12-M16 | 6-M33*580mm |

| 1000 | 1012 | 600 | 325 | ±25 | 50 | 1255 | 1175 | 1048 | 1133 | 24-36mm | 12-M16 | 6-M33*600mm |

| 1200 | 1216 | 640 | 340 | ±25 | 57 | 1490 | 1410 | 1255 | 1368 | 32-36mm | 16-M16 | 8-M33*640mm |